Montero - the way forward for gasket material recycling

In recent years, there has been a notable surge in interest and research within the industry aimed at adopting a circular economy model as part of broader sustainability initiatives. This movement is indicative of a heightened awareness regarding environmental issues, resource limitations and increasing demands from consumers and regulatory bodies. Transitioning to this model often necessitates a significant shift in mindset and typically involves a transformation of business practices. The circular economy offers a sustainable alternative to the conventional ‘take-make-dispose’ approach. Its implementation is gaining momentum due to its ability to minimise environmental impact, enhance resource efficiency and reimagine traditional supply chains. Collaborative efforts among businesses, governments and innovators are essential to making this transition viable and adaptable on a global scale.

Fig.1: Gasket sheet cuttings

Fig.1: Gasket sheet cuttings

The circular economy is poised for significant growth, propelled by advancements in technology, such as artificial intelligence in waste management, along with supportive policies and increased investments in sustainable practices. Industries are beginning to reframe their approach to sustainability, recognising it as a catalyst for innovation and growth rather than merely a cost. Small and medium-sized enterprises (SMEs) are vital to this evolution. Despite having fewer resources than larger firms, their agility and innovative capabilities often position them as leaders in promoting circular practices.

These practices may involve enhancing energy efficiency through the use of energy-saving equipment to minimise waste, prioritising renewable materials by substituting single-use items with sustainable, biodegradable or recycled options, and identifying waste produced during manufacturing to find reusable or recyclable materials. The gasket manufacturing sector is particularly important in the transition to a circular economy. Their products are essential for sealing systems, preventing leaks, and ensuring energy efficiency, which aligns closely with circular economy principles. For these companies, embracing circular economy strategies could lead to substantial improvements in competitiveness, cost reductions and enhanced customer loyalty.

In recent years, we have been dedicated to implementing and investing in innovative sustainability practices, seamlessly incorporating these principles into our operations. Our primary aim is to fulfil both strategic and ethical objectives. One notable initiative involves the production of gasket materials, specifically by utilising recycled micronised structural waste generated from gasket material sheets. This waste arises from structural considerations, often becoming discarded due to specific customer dimension requirements that lead to sheet cuts, or when the entire sheet cannot be utilised because the requested supply format differs from the manufacturing format, Figure 1. Nevertheless, this material can be transformed into raw material, thereby greatly minimising environmental impact.

This process is being implemented as follows. Generating recycled raw material

- Cleaning and pre-treatment: depending on the source, the material may require pre-treatment before further processing.

- Grinding, pulverising or micronising: larger waste pieces are ground into smaller particles or powders, making them easier to process and mix with binders, Figure 2.

Blending and compounding

- Formulation: the ground waste material is blended with binders and fillers in precise proportions to achieve the desired mechanical properties.

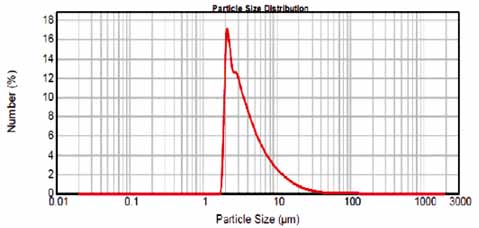

- Particle size: the size of the particles is critical in determining the performance and quality of the micronised material used in gasket formulations, Figure 3.

Sheet formation process

- Calendering: the compounded material is passed through a calendering machine, which compresses it to form uniform sheets of a consistent thickness. This process ensures both the desired thickness and high-quality surface finish of the material.

The role of micronised gasket powder

Gasket sheets and various vulcanised rubber products frequently pose disposal difficulties because of their durability and resistance to breakdown, leading to possible environmental risks in landfills. To address this issue, recycling initiatives have focused on reclaiming these materials by transforming waste into a fine powder, which can subsequently be incorporated into new gasket formulations. This recycling approach minimises resource use and decreases waste production.

Gasket sheets and various vulcanised rubber products frequently pose disposal difficulties because of their durability and resistance to breakdown, leading to possible environmental risks in landfills. To address this issue, recycling initiatives have focused on reclaiming these materials by transforming waste into a fine powder, which can subsequently be incorporated into new gasket formulations. This recycling approach minimises resource use and decreases waste production.

The objective is to integrate sustainable production methods by repurposing waste materials, employing energy-efficient techniques and reducing emissions. This approach guarantees superior quality outcomes while fostering environmental responsibility. By leveraging recycled gasket materials, manufacturers can realise cost efficiencies without compromising on performance and durability. Consequently, these materials are well-suited for a range of industrial applications and support overarching corporate sustainability initiatives, offering both ecological and economic benefits.

Impact of micronised gasket powder on gasket performance

Challenges

A major obstacle in utilising micronised gasket powder lies in achieving performance equivalence between new formulations incorporating this recycled material and their original counterparts. The introduction of recycled raw materials can influence various mechanical and chemical properties, including elasticity, tensile strength and chemical resistance, potentially compromising the sealing efficiency and durability of the final product.

Incorporating micronised waste powder into new gasket formulations demands specific processing methods to ensure compatibility. It is essential for the recycled powder to integrate seamlessly with the formulation to preserve consistency in both texture and performance. This requirement may lead to additional stages in the manufacturing process, thereby increasing its complexity. Particle size plays a crucial role in this process. The elastomeric matrix needs to fully utilise the surface area development (m2/g).

- Smaller particles = higher surface area: reducing particle size increases the surface area-to-volume ratio, enhancing properties like adhesion, mixability and mechanical performance.

- Fine control: Optimal particle size ensures that the surface area aligns with the material’s intended use, balancing strength and flexibility.

Reducing particle size enhances surface area, but overly fine particles can cause problems such as clumping and dust generation, which complicate processing and uniformity. Very small particles may also diminish the mechanical properties of the gasket, undermining its structural integrity. On the other hand, larger particles can produce rough and uneven surfaces, which decrease sealing efficiency and may result in leaks under pressure. Additionally, they can introduce weak points in the gasket, affecting its durability, thermal resistance and chemical resistance.

Opportunities

Sealability refers to a gasket’s ability to create a tight seal under varying conditions, making it a crucial factor in evaluating gasket performance. Integrating recycled micronised powder could influence this in the following ways:

- Filler effect: micronised powder can act as a filler that enhances the density and bulk of the gasket material. When appropriately dispersed, this filler effect can reduce porosity, potentially improving sealability by preventing fluid leakage under pressure.

- Recycled fibre-enhanced materials: adding micronised powder from recycled fibre-reinforced rubber brings sustainability benefits. However, its impact on mechanical properties and sealability requires careful adjustments in formulation. Key factors like particle size, distribution and material compatibility must be optimised to improve seal performance while preserving other important mechanical properties.

Fig. 3: Particle size distribution

Fig. 3: Particle size distribution

Risks

The particle size of micronised powder can significantly impact the risks associated with the gasket sheet manufacturing process.

- Safety: fine particles increase the risk of airborne dust during handling and processing, which can affect air quality and worker safety. Small particles are more likely to become airborne, posing inhalation hazards. Manufacturing facilities may need advanced ventilation and dust-collection systems to control fine particulate matter, adding operational complexity and cost.

- Equipment abrasion: fine, abrasive particles can accelerate wear on machinery used for mixing, pressing and milling. Equipment like grinders and mixers may suffer more rapid degradation when processing finer particles, leading to increased maintenance and downtime.

- Static charge: micronised powders, particularly finer particles, are prone to accumulating static electricity. This poses fire and explosion risks in facilities handling fine powders, especially in the presence of other flammable materials. Implementing grounding and anti-static measures can mitigate these risks, though they add safety and infrastructure requirements to the manufacturing process.

- Process efficiency and flowability: very fine powders can cause issues with flowability, which impacts material handling during mixing and pressing stages. Poor flow can lead to blockages in equipment and inconsistencies in product density, making it harder to achieve uniformity in the final gasket material. Coarser particles generally flow better but may compromise the final product’s mechanical properties, requiring a balance in particle size to optimise both flow and performance.

- Quality control challenges: smaller particles require more precise quality control measures to ensure consistent distribution throughout the gasket sheet material. Fine particle distributions can vary significantly with minor process fluctuations, making it essential to monitor and control particle size rigorously. This need for tight control can add complexity to quality assurance processes, requiring advanced monitoring equipment.

Sustainability benefits of recycled gasket material powder: a strong case for ongoing research

Recycled gasket material powder presents considerable sustainability advantages by minimising waste and conserving valuable resources. By transforming discarded gasket sheets into micronised powder, manufacturers can effectively repurpose materials that would otherwise contribute to landfill accumulation, thus reducing the environmental footprint of production activities. This recycling initiative lessens the reliance on virgin raw materials, aiding in resource conservation and lowering the carbon emissions linked to material extraction and processing. Additionally, utilising recycled materials in new gasket formulations can reduce raw material expenses, offering a cost-effective alternative to entirely virgin materials. This circular economy approach not only fosters environmental stewardship but also meets the increasing consumer and regulatory demand for sustainable products. By enhancing sustainability practices, companies can play a pivotal role in promoting a circular economy, where waste is minimised, and material lifecycles are extended. The incorporation of recycled materials into industrial products such as gaskets supports corporate sustainability objectives while ensuring performance and durability standards are upheld, striking a balance between environmental and business interests. In summary, effectively managing the risks related to particle size in micronised powder requires a careful balance of material characteristics with safety protocols and process controls. While these considerations may elevate operational costs, they are crucial for ensuring worker safety, equipment durability and product uniformity.

A comprehensive study on sealing performance variation in products that include a small percentage of recycled material within a traditional formulation has demonstrated enhancements of 15-20% in sealability values, as per DIN 3535:5 2020-07. This underscores the commitment to a circular economy, where the integration of recycled material from structural rejects in sheet manufacturing is an integral part of the overall management strategy, effectively minimising resource use and waste while ensuring safety.